Focus on liquid level meters and radiation detection instruments

to create a leading brand in the liquid level meters and radiation detection instruments industry

ChineseClick Here

Level instruments

Position: Home > Level instruments > Magnetostrictive level transmitter Magnetostrictive level transmitter

Product category: Magnetostrictive level transmitter

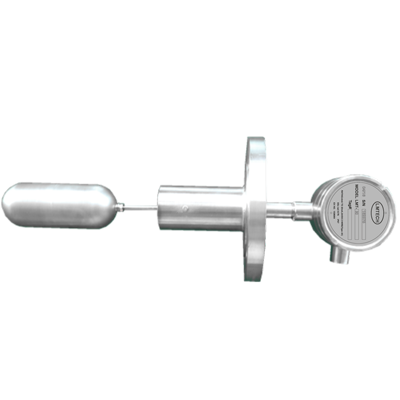

Product name:Lmt-300 series magnetostrictive liquid level meter

Product Details

Overview said

LMTECH magnetostrictive liquid level gauge is an innovation with integrated intelligence, high precision and high reliability

Technical product, its birth has solved the measurement of liquid level and boundary level under extremely harsh working conditions. Its products

The principle determines that the measurement process is not affected by changes in temperature, pressure, dielectric constant and other factors,

Set the advantages of high precision, high stability, high anti-interference ability, maintenance-free, etc., make up for the electric float level

And other liquid level measurement products such as pressure gauges, differential pressure transmitters, radars, etc.

foot. It is widely used in liquid level and interface measurement in electric power, petrochemical and other industries.

Product technical features

● Accuracy up to 0.01% FS (Full Scale), repeatability reaches 0.005% FS

● Can simultaneously output two 4 ~ 20mA analog quantities, used to detect liquid level, boundary or temperature, and can measure up to 5 temperature points at the same time

● With Hart Communication Association, PROFIBUS PA bus, MODBUS (RS-485) bus

● Electronic modules can be exchanged on site for easy testing and maintenance

● Maintenance free, no need for secondary calibration

● The zero point and full scale position can be set arbitrarily on site

● Split reading and on-site indication are optional

● Optional remote transmitter

● No need to recalibrate, set once, permanent memory; the only movable part is float, maintenance amount

Very low and extremely stable.

working principle

After energization, the electronic component sends out a current interrogation pulse.

At the same time, a magnetic field is generated to move down the waveguide, when the magnetic field generated by the current pulse

When intersecting the fixed magnetic field of the magnetic float, a torsional stress wave, or return pulse for short, is generated

Impulse, because the propagation speed of the return pulse in the waveguide is fixed, so through accurate

Measure the time interval between the interrogation pulse and the return pulse to obtain high precision,

Highly repeatable level values.

Application range

LMT magnetostrictive liquid level gauge can be used for liquid level industrial gauges of various liquid tanks in power, petroleum, chemical raw material storage, metallurgy, tank area management and gas station

Quantity and control, dam water level, reservoir water level monitoring and sewage treatment liquid level monitoring, etc.

· Power generation industry: high / low addition, deaerator, condenser, boiler steam drum, hot well, water tank, oil tank, heating network heater, chemical water treatment, desulfurization and de-sold project

· Petroleum industry: oil pipelines, gas stations, tank trucks, oil fields, oil refineries, oil and gas exploitation and gathering, oil refining, ethylene, trimerization, etc.

· Chemical industry: tank farm, chemical pool, etc.

· Coal chemical industry: methanol, dimethyl ether, synthetic ammonia / urea, coal to olefins, coal to oil, coal to natural gas

· Fine chemicals: methane chloride, ethylene oxide, aniline, PTMEG, BOD, carbon fiber, polyoxymethylene, acetic acid, styrene, rubber, crude and refined

· Metallurgy industry: cooling water treatment

· Water treatment industry: oxidation tank, sedimentation tank, etc.

- Home

- |

- About Us

- |

- Level instruments

- |

- Download

- |

- Contact Us

Phone:+44 1582806885 Email:sales@lmtechins.com

Add:18A LANCHESTER WAY,ROYAL OAK INDUSTRIAL ESTATE,DAVENTRY,NORIHAMPTONSHIRE,ENGLAND

Copyright © LMTECH Co. Ltd. No reproduction without permission