Focus on liquid level meters and radiation detection instruments

to create a leading brand in the liquid level meters and radiation detection instruments industry

ChineseClick Here

Level instruments

Position: Home > Level instruments > Electrode level switch Electrode level switch

Product Details

The working principle

is measured by the characteristics of the conductivity difference between water and steam in the measured container. Due to the change of the liquid level, some electrodes are immersed in water, and

some electrodes are placed in steam. The electrode placed in the steam has an increased resistance to the barrel.

Using this feature, the water level of non-electricity can be converted into electric power and sent to the intelligent secondary instrument, so as to realize the functions of water level display, alarm,

protection and interlocking.

Technical characteristics

◎ No movable parts, small space. The system is simple, saves valves, the measuring principle is simple, and is not affected by changes in

industryand mine;◎ The sealing of the electrode and the measuring cylinder adopts the US SWAGLOK seal, which can ensure long-term operation without leakage in the high temperature and high pressure state;

◎ LMJ electric contact liquid level gauge produced by LMTECH long-term non-oxidizing electrode design / material / manufacture is to ensure interface security

installation requirements downwardly steam pipe hydrophobic measuring cylinder steam flows continuously take over the connection from the container to the high temperature and pressure measuring cylinder,

the hydrophobic aspect heating measurement cartridge low temperature medium level compensation functions; aspect of the medium is a continuous flow of

moving, to ensure that the medium is a measuring cylinder cleaning / non-fouling;

◎ LMTECH production LMJ electrical contact level gauge installation site and debugging is very simple

◎ LMJ level gauge electrical contacts have been considered in the design of the pressure vessel due to the different measuring cylinder and two sides medium temperature resulting density

of the difference results in the difference compensation level, both in hot or in cold, reflecting The water level is accurate;

◎ LMJ adopts a large number of high-precision electrode sensors with limited working conditions, and the measuring range exceeds the diameter of the steam drum. Furnace can be accurately taken before and after the

sample measurement, and may be protected with a drum water level, the boiler missing / full water forced shutdown measured values accident, and whether the water is determined

When water is added, it can assist the cooling operation and monitoring of the steam drum full water after the furnace is stopped.

◎ LMJ case where the electrical contact level switch may be used in combination with a magnetic level gauge, the device reduces both the openings ensure that the system messages

need to police, increased local display function. If the traditional solution is to achieve the above functions, it is necessary to separately install a magnetic flap level

gauge and a float level switch, which causes hidden safety hazards such as leakage caused by equipment openings, and the cost is relatively high.

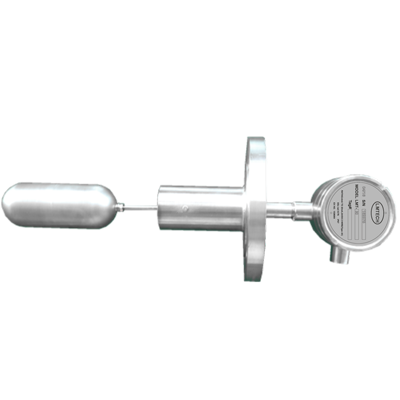

LMJ high-precision sampling electrode sensor

◎ High-precision sampling: In any case, the water sample is saturated temperature, as if the electrode is directly installed on the steam drum, the measurement is

true, the dynamic response is fast, and the additional error is small.

◎ High reliable sensing: self-optimization of water quality, free sewage, electrode receiving little impact, no pollution, long electrode life,

not leak within three years, not linked to water

◎ measurement accuracy: differential Pressure water level check all condition, can be put into water protection boiler starts

Specifications

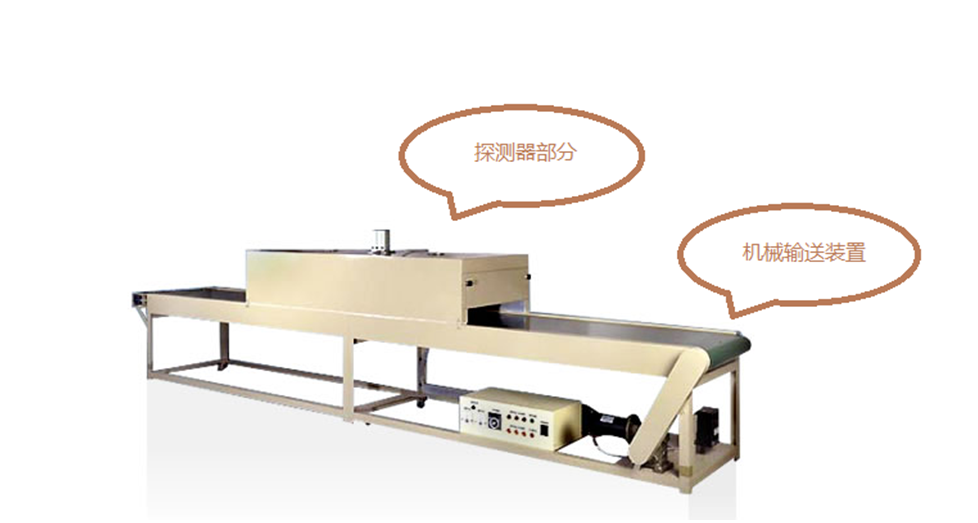

intelligent level detector

Working environment temperature: -20 ° C ~ + 65 ° C

Working relative humidity: <85%

Applicable liquid resistance range: 0 ~ 300KΩ

Electrical contact lead length: <200m

Output contact capacity: 10A / 250VAC

Power supply voltage: 220VAC (± 10%), 50HZ

whole power consumption: <10VA

output: 4 ~ 20mA, RS485 optional

◎ high fault tolerance - damaged portion of the electrode is still accurately indicate the correct level, and the display electrode damage immediately

◎ high noise immunity - The use of photoelectric isolation and digital filtering technology greatly improves the anti-interference ability and completely solves the problem of false alarm at the instant of turning on the old-fashioned instrument

◎ Scale numbers and alarm points can be set freely

◎ Electrode automatic test function-each electrode is tested individually to find abnormal electrodes in time, for electrode

cleaning or replacement, water vapor resistance critical value provides a reference

◎ Compatibility-detector can be Free replacement

electric contact liquid level meter

Application case of intelligent liquid level controller Application of

boilers in the power industry, high and low heating, steam trap condenser, deaerator, steam pipe liquid level, alarm protection or interlocking

Petroleum, chemical, food, pharmaceutical

LMJ 300 Type technical parameters

Application Boiler drum water level / high pressure heater / low pressure heater / deaerator / drain tank condenser water level measurement, water level alarm or interlocking

number of electrodes 1-- ~ 19 optional

electrode materials stainless steel / zirconia Or stainless steel / Teflon

cavity material Stainless steel, carbon steel, other alloys are optional

Supply voltage 220VAC 50 ~ 60HZ

Relay contact capacity 10A @ 120VAC 8A @ 24VDC

Output model 4 ~ 20mA

Working pressure 3000pai

Operating temperature 538 ° C

Minimum resistance 0.5 microohm

Protection grade NEMA 4X IP67

function Interlocking control / alarm output / circuit on / off status detection / local fault display / can be designed according to customer requirements

- Home

- |

- About Us

- |

- Level instruments

- |

- Download

- |

- Contact Us

Phone:+44 1582806885 Email:sales@lmtechins.com

Add:18A LANCHESTER WAY,ROYAL OAK INDUSTRIAL ESTATE,DAVENTRY,NORIHAMPTONSHIRE,ENGLAND

Copyright © LMTECH Co. Ltd. No reproduction without permission